How did the SIGMA 16 project come about?

Eugénie Viard-Gaudin: “After 15 years in our range, the HA15 IP is reaching the end of its life cycle and as it is very important for our range, it needs to be replaced. The aim was to produce an electric platform for stabilized ground that satisfied Haulotte’s innovation and safety standards. We started from scratch to design the SIGMA 16 with a new architecture.”

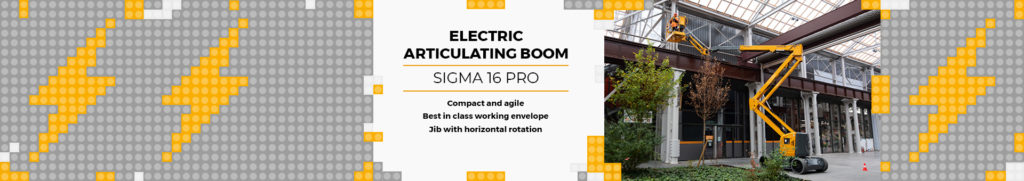

Benoit Baleydier: “Our aim was to design a versatile, agile platform that could be used for multiple applications, with a work envelope making the machine as efficient as possible. It had to be compact to work in a crowded environment like a warehouse, and also outside on stabilized ground. These criteria are essential for our customers, who want a machine that is efficient and simple for users.”

What were the design criteria for this new platform?

Eugénie Viard-Gaudin: “We wanted the SIGMA 16 to be a machine that is as productive as possible, offering the best work envelope on the market, i.e. the perfect balance between the working height, the reach and the up-and-over clearance. Our challenge was to maximize its movements whilst remaining within the chassis envelope. The real strength of this machine is its ability to combine two movements to reach the working area faster. We have also introduced a horizontally rotating jib, something new in this segment, to access areas more quickly and get to even the most hard-to-reach work zones. All of this improves productivity. We have taken user comfort into consideration of course, by reducing jolting on the platform.

Lastly, we have optimized serviceability to reduce maintenance costs, increase availability and satisfy our customers’ expectations. We have also worked very hard on designing the routing for hydraulic hoses and electrical cables, making them more understandable and easier to maintain or change.”

Benoit Baleydier: “The teams in the design office worked on the digital modeling of the machine at a very early stage in the design phase to make sure all the needs were taken into account. Tests enabled us to confirm that the machine satisfies the needs and complies with the applicable standards. This is crucial work that allows challenges to be identified at a very early stage.

What exclusive Haulotte innovations are incorporated into the SIGMA 16?

Benoit Baleydier: “SIGMA 16 is equipped with the safety innovations from the RTJ range. It has the Activ’ Shield Bar, the anti-entrapment system for improved safety when working at height, and the Activ’ Lightning System, LED lighting to facilitate loading and unloading in low light conditions. It has the completely new Activ’ Energy Management, with a smart charger as standard on both models, and centralized battery filling on the SIGMA 16 PRO (available as an option on the SIGMA 16).

Above all, this project was about teamwork. How did the conditions linked to the health crisis affect the development of the SIGMA 16?

Benoit Baleydier: “The project team was composed of around ten people from several departments: purchasing, quality, marketing, the design office, regulations, industry, logistics, research and development, test center, etc. Most of the company’s departments participated in this project, even our plant in Romania, to which we made several trips when it was possible in 2020. During the lockdown periods, we sometimes held reviews or validations on the machines by video-conference. For example, the routing was validated by video-conference between Romania and France. This period was a real challenge but the teams always managed to come up with solutions. We hugely reinvented our working methods.

Eugénie Viard-Gaudin: “Due to the health crisis, training for the sales and technical teams has been done remotely, by video. The project team was heavily involved, since we were actors in the video training modules. We had to be creative. The team members were able to explain their role in the project, and some contributed to the detailed presentation or were able to explain their expertise in front of the camera. It was a very enriching experience, because up to now, the project teams were not very involved in training. Everyone was able to explain their job, step into the limelight and out of their comfort zone. It was a great human adventure.”

Production launch for the new SIGMA 16s has been validated. The project team has passed the baton to the sales team: learn more in the video!

A lire aussi

Loxam: Haulotte in pole position

As part of its supplier monitoring program, Loxam Access carries out an annual satisfaction survey with its teams. For Loxam,...