We must therefore strengthen our presence in the country to meet demand and deal with a booming competition! Our strategic project “Boosting our growth in China” mobilizes teams around the world to build a new factory model in Changzhou that is technological, efficient, and secure.

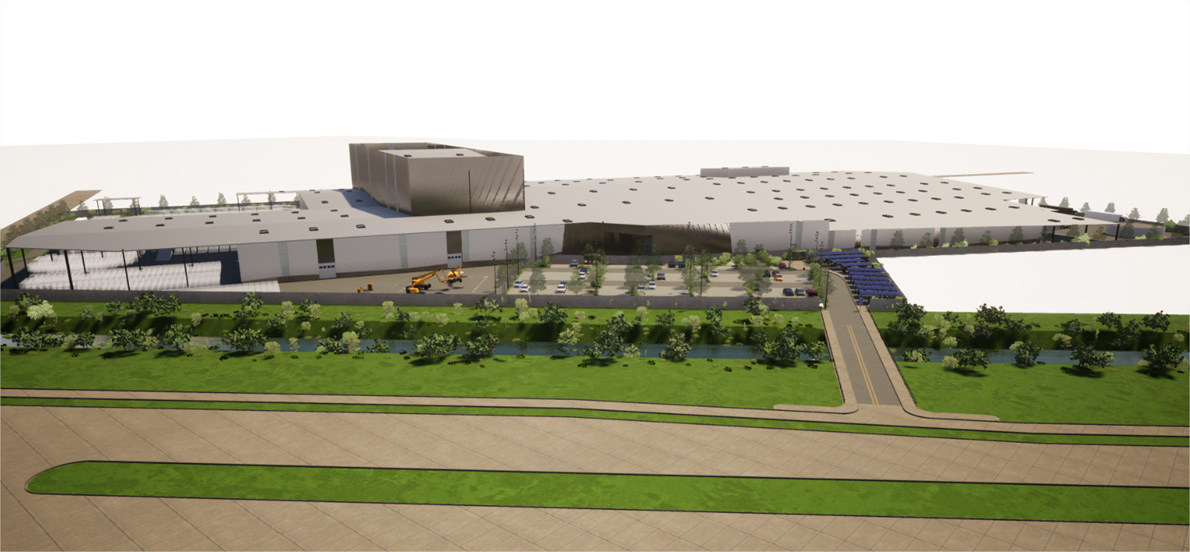

After months of preparation, the Changzhou plant project is now taking a decisive step: Haulotte will soon own land near the current site. A building will soon be erected here to house our Chinese teams, which will be gradually reinforced with support and production. Construction is scheduled to start at the end of 2020, opening in the first half of 2022.

Our teams are currently working on developing new processes to improve existing protocols. “We have collected as many best practices as possible from all of the Group’s sites, benefitting from everyone’s experience,” explains Hubert Moreau, Director of Industrial Projects (L’Horme, France). Three essential areas will be radically transformed using innovative solutions: digitalization, workstation optimization, and safety.

Opened in 2008/2009, the current factory is reaching saturation point and does not have the means to meet our production needs. It only manufactures a third of the range and does not include the paintwork. Ultimately, the new site will carry the entire Haulotte range, from 6 to 43 meters: an unprecedented production capacity within the Group! “This factory will be used to supply all of Asia, with priority given to China to consolidate the 10% market share that we are currently achieving in the country”.

Consolidating all of our strengths

The Changzhou plant project extends far beyond the borders, breaking down barriers between employees. “We integrated the teams, then all of the factories, to define a production model that was consensus-based. The Chinese teams are, of course, at the heart of the system, particularly the sales teams, which will be established on the industrial site”. This dynamic will make it possible to identify good practices among 25 strategic topics relating to processes and the working environment. This vision involves as many people as possible and skills to synthesize the best ideas and develop an innovative factory model compared to what already exists.

It’s a big honor to take part in the Changzhou 2 project. We have collaborated closely with Hubert and his team. Hubert involved us in the design and was responsive to the subsidiary-related requirements, as our service activity will be installed on this new site. We proactively expressed our needs to Hubert. We also provided advice on how to align our new factory with the needs of the rapidly growing Chinese market: multi-phase production, for example. It’s a work team that will build a magnificent Haulotte factory!

I am responsible for developing the network of raw material suppliers needed to manufacture the new machines at the new Changzhou site.

In terms of strong growth, the new factory will ensure that the Haulotte Group to settles permanently in the Chinese market. I am very proud to be a part of this great and exciting project!

I work closely on a daily basis with the central purchasing department to implement our procurement strategy.

We hold a weekly update with the management teams located in France, Romania, and China to take stock of the project’s progress: it is a fine example of international collaboration and teamwork.

Being responsible for the project’s Supply Chain and Lean functions, I am involved in working with the current sites, focusing mainly on the organization and implementation of flows.

And that’s just the beginning!

We will form inter-site improvement groups to optimize our practices and implement them on the Changzhou 2 site.

This approach relates to the entire flow: suppliers, packaging, reception, storage, preparation, distribution on production lines and machine shipments.

Multiple actions are also supported as part of the project:

We involve internal and external business experts in all of these issues, bringing our experiences and feedback from improvement groups.

In terms of industrialization, this new factory is a challenge because it will be a mix of all the other sites; however, the constraints for producing an Optimum 8 or an HT43 are completely different!

We have established the specifics of this new building, based on the group’s industrial experience and personal feedback from the teams. A lot of employees have sent their ideas to us (R&D, quality, industrialization) and workshops were organized to achieve our objectives together. This will serve not only this construction project but all of the factories within the Group as well!

This experience is really interesting because I have learned a lot about construction. I have never experienced this before, and I often had to do research to understand certain technical proposals!

Daily discussions with our potential suppliers are also necessary to explain our needs to them and ensure that they can meet our level of requirement.

and stay informed of the latest news and events from the Haulotte Group’s internal communication!